In the fall of 2007, workers at the Byron nuclear power plant in Illinois were using a wire brush to clean a badly corroded steel pipe — one in a series that circulate cooling water to essential emergency equipment — when something unexpected happened: the brush poked through.

In the fall of 2007, workers at the Byron nuclear power plant in Illinois were using a wire brush to clean a badly corroded steel pipe — one in a series that circulate cooling water to essential emergency equipment — when something unexpected happened: the brush poked through.

The resulting leak caused a 12-day shutdown of the two reactors for repairs.

The plant’s owner, the Exelon Corporation, had long known that corrosion was thinning most of these pipes. But rather than fix them, it repeatedly lowered the minimum thickness it deemed safe. By the time the pipe broke, Exelon had declared that pipe walls just three-hundredths of an inch thick — less than one-tenth the original minimum thickness — would be good enough.

Though no radioactive material was released, safety experts say that if enough pipes had ruptured during a reactor accident, the result could easily have been a nuclear catastrophe at a plant just 100 miles west of Chicago.

Exelon’s risky decisions occurred under the noses of on-site inspectors from the federal Nuclear Regulatory Commission. No documented inspection of the pipes was made by anyone from the N.R.C. for at least the eight years preceding the leak, and the agency also failed to notice that Exelon kept lowering the acceptable standard, according to a subsequent investigation by the commission’s inspector general.

Exelon’s penalty? A reprimand for two low-level violations — a tepid response all too common at the N.R.C., said George A. Mulley Jr., a former investigator with the inspector general’s office who led the Byron inquiry. “They always say, ‘Oh, but nothing happened,’ ” Mr. Mulley said. “Well, sooner or later, our luck — you know, we’re going to end up rolling craps.”

A North Dakota judge has said he will order Greenpeace to pay damages expected to total...

A North Dakota judge has said he will order Greenpeace to pay damages expected to total... Donald Trump has vented his fury against a green energy deal between the British government and...

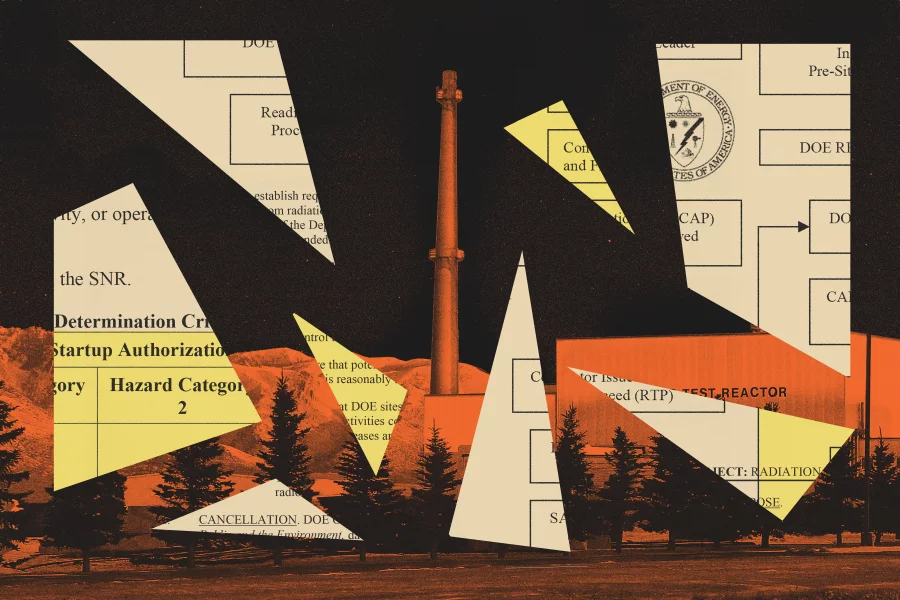

Donald Trump has vented his fury against a green energy deal between the British government and... The Trump administration has overhauled a set of nuclear safety directives and shared them with the...

The Trump administration has overhauled a set of nuclear safety directives and shared them with the...